NestEgg Labs aims to combat waste in research laboratories through automation and standardization.

FundsUp spoke with Tanner Carden and Heena Uijttenboogaard, respectively the founder/CEO and the new Commercial Growth Manager of the startup. With backgrounds in biology and chemistry, they address inefficiencies in cell culture laboratories through automation. They aim to standardize research practices and reduce plastic waste while seeking investors to support their growth, with support from organizations like Utrecht Inc.

A Dutch version of this article can be read on the website of our partner: Emerce.

Who are you and how did you get to where you are now?

Tanner: “I’m Tanner. I founded NestEgg Labs. And this is Heena. She’s our newest team member. She’s the new growth researcher for the company.”

Heena: “So I’m responsible for all the commercial growth that we can bring to the market and convert into business growth.”

Tanner: “And as founder and CEO, I manage administration, setting big goals, and currently a lot of business development.”

What are your backgrounds?

Tanner: “So I researched biology at the University of Alabama. Besides the research, I have been involved with basically running tech development projects, managing them, and submitting and running grant based projects.”

Heena: “-and I have a degree in chemistry and also minors in botany and zoology. But my work experience has been more on the commercial side of the sciences sector.”

And how did you get to come to the idea of Nest Egg Labs?

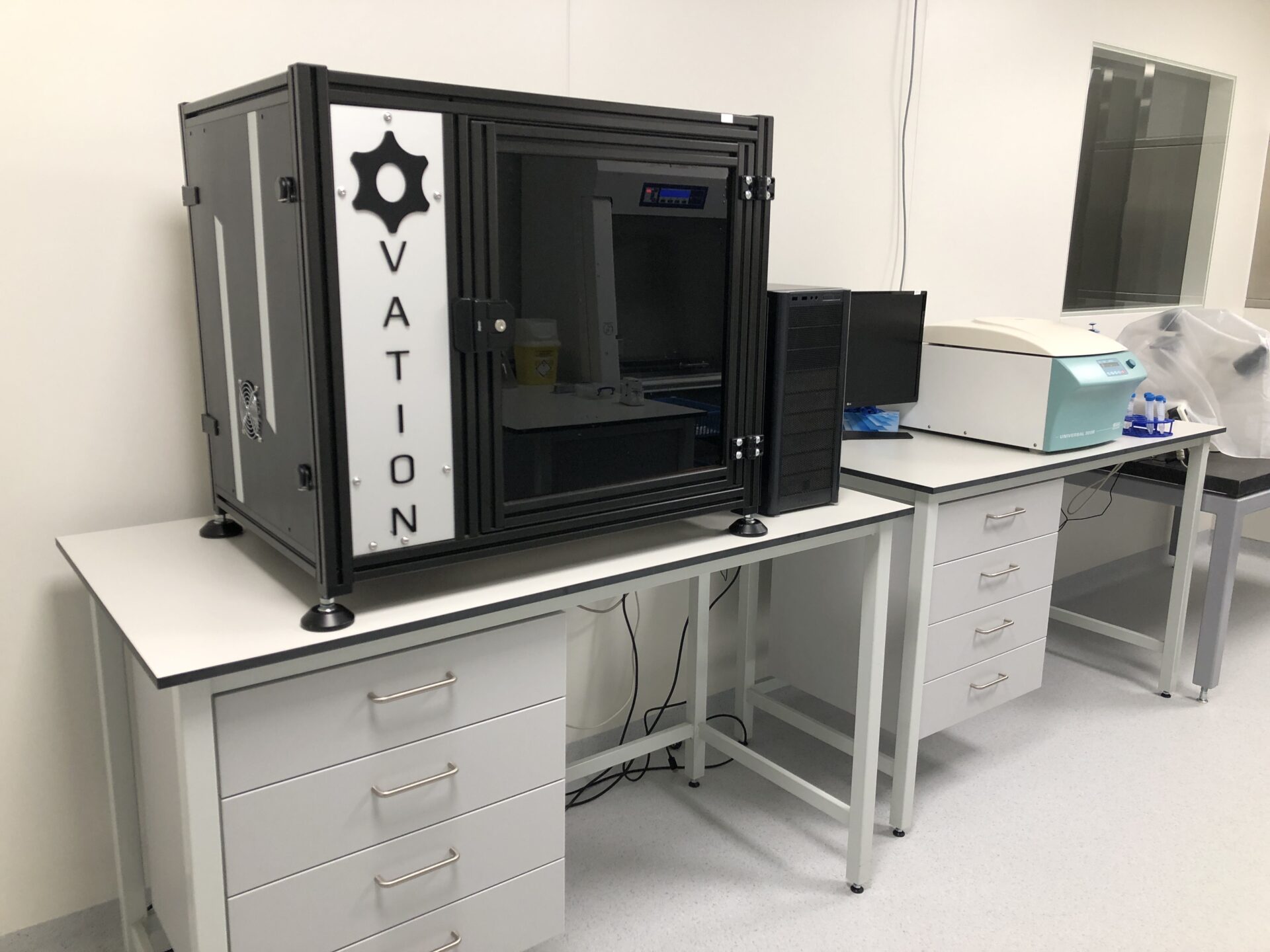

“So, during my work at the University of Alabama, I saw a lot of unused lab equipment and I saw a lot of manual work. And I came to find out that this is increasingly still something that goes on in even the most modern cell culture labs, that there’s still a huge amount of manual work and there’s still a huge amount of variability and there’s a huge amount of waiting around and not using the equipment that may be for a very specialized purpose. So we found out there’s a lot of inefficiency in this. And we had an opportunity to acquire some IP for cell culture automation, and we thought we could use that to make the whole process more turnkey and to disrupt the failure we see as currently inherent in the modern cell culture lab.”

Can you tell us a bit more about cell culture?

“Understanding cellular behavior is crucial for disease management and drug development. Currently, a lot of biomedical research fails, often due to limitations in cell models. In vitro testing offers a promising solution, allowing early-stage drug evaluation without risking human subjects. However, existing cell models poorly mimic human tissue, necessitating better alternatives. Recent FDA regulations phasing out animal models underscore the urgency for improved, replicable cell-based models. Bridging this gap is essential for faster, safer drug development and addressing critical research needs.”

And what is in the moment at which you can decide it’s ready for patient?

“So there’s three steps in clinical trials. Most drugs fail in the early stages, and the more, the further it goes through the process of clinical trials, the more expensive that failure becomes. So you want to find out as early as possible, preferably in preclinical testing, that your new medicine is not going to work. You want to find that out before you go through a couple of years of clinical trials. And so it is very rigorous to bring new medicines to market. But you basically don’t want to invest a whole bunch of money if it’s going to fail later.”

You’ve already spoken to research institutes or hospitals to pitch this idea?

“So we have built some automated technology to test and to validate its use case with these researchers. So we’re working with University Maastricht already on a grant project and looking to validate it with more research labs. In total, we’ve had about twelve different labs that signed letters of intent to try our technology. Some have even paid us, and we have some clients that are already paying for customized versions of what we built for their special use case. So we’ve already done the market validation part in the last year or two. We did some surveys and did some collaborative projects, like I mentioned, and then we saw some early sales. So we consider that validation with the market.

Heena: “The question is, how many of these can we get into larger facilities and larger organizations that are maybe more industrialized or have different needs than the small scale researchers.”

How is it then adopted by them?

“So what we built is very turnkey in the sense that it works with what they already have. A lot of other pieces of kit out there require researchers to make big changes or to do extra training. We basically provide them with a quick start guide, and we do a little bit of pre testing interview to make sure that what we’re giving them is going to work for their needs. But ideally, they shouldn’t need much training. They shouldn’t need to adapt much. We should build things that adapt to them. And the trick is doing that in one focused bill of materials that isn’t all over the place, because this is very different depending on the needs of researchers. Luckily for us, they all use very standardized dishes and plates.

So we have designs that fit onto most standard plates and that therefore, researchers don’t need to change that part of their work. They can continue that part, same as they had before, just by doing fewer steps.”

Can you quantify the impact that will have? Is there already some data you have on that?

“Yeah, we have some estimates, and we have some feedback on the usability. Generally, these researchers like the idea of not having to manually do things by hand anymore and to have less instances of contamination. So that’s been the initial feedback. We’re still collecting testimonials right now to hopefully publish and to promote our product and actually put some key opinion leaders’ names up on the board next to our products. So that’s coming in the next month or two, hopefully. But then we think, as far as our estimates go, that we can have the biggest impact on the sustainability of these labs, because a lot of these labs are built around single-use products that are disposable, and that really adds up. So researchers may go through as much as 60 kilos of single-use plastic waste per researcher per year.

And we think we can reduce that by around 96%. Yeah, I think if you take the average number of average lab, when it comes to wastage per year, I think the number is around 273 kilos of waste. And then we are. We will. Our plan is to get it down to nine kilos. What currently we can do at the moment is nine kilos per year. So that is a significant reduction just on the matters of sustainability alone.”

How do you plan to roll out?

“Our mission is to simplify research, akin to riding a bike. We aim to standardize research practices across labs, encouraging transparency even in failure. Automation and AI will optimize this process. Over five years, we’ll expand into various markets, focusing on pharma and contract research labs. Instead of scaling up sample sizes, we’ll automate and standardize, enabling remote work and enhancing replicability. And indeed, the ultimate goal is to speed up and accelerate the number of new cell based therapies or products that come to market per year. That’s our overall “big hairy goal”.”

How do you intend to commercialize it, also in regard to IP?

“Yeah, so we have some IP already granted. And then we also have some IP that we’re filing, some patent protection we’re filing. And then the hardware we build is pretty off-the-shelf. It’s not super patentable, but the consumables that we develop are the core of our IP and that’s what we’re protecting. So we use a very reliable razor and blade model where we sell a piece of hardware for some margin, and then we sell consumables over time and those consumables have a better margin. So that’s kind of the proven strategy. And then of course, to run automated systems, you need software. So we also have ways of monetizing the software and protecting that as well.”

What are you currently looking for?

“So we currently have around 600k soft-circled. Some of that is already committed in our seed round, and we’re looking for investors that invest in early stage companies, but they’re looking for a high growth over time. As a biomedical startup, we have a little bit of a longer time to exit than other companies. However, we’ve already done so much of the technological development that right now a lot of that runway is already completed. So there’s not a long development timeline. We’re already having pre-sales, and we’re already in the labs with some customers in the UK, in the Netherlands and in the US.

So we’re looking for investors that are excited by that kind of traction and that want to join the round along with deep tech investors that we’re talking to, especially investors that have a portfolio in life sciences and can have a value add to our board of directors someday.”

We recently met again at Utrecht Inc. How has your experience been there?

“So Utrecht Inc is a really nice ecosystem for these startups here and they’ve been really kind and going out of their way to help introduce us to this region and put us in front of regional players that might be interested in funding or helping us. Utrecht Inc provides invaluable support for startups like ours, facilitating connections with regional stakeholders and researchers. With Utrecht Science Park housing around 4000 researchers, many engaged in cell-based work, it’s a pivotal hub in the Dutch life sciences ecosystem. By establishing a stronger presence here, we aim to better serve labs in the region. Utrecht Inc has been instrumental in our initial steps, and we’re optimistic about further collaboration and growth in this promising ecosystem.”

Finally, do you have any advice you’d give to other entrepreneurs?

“I say get comfortable with failure and experimentation, especially in startup environments. Being honest and resilient in the face of failure is crucial for growth and learning. Don’t wait for perfection; start sharing your product early, gather feedback, and iterate based on real-world usage. This approach fosters innovation and prevents valuable ideas from languishing unused on the shelf.

Our Seed Round is open on FundsUp now, and we are raising 1.6 million euro total. This round finances the increased marketing and business development activity we have planned, as well as the final development of our technology up to a version ready for manufacturing and certification. This market is growing fast but we are ahead of the curve, what we’ve already developed is significantly more affordable, sustainable, and integrated than the status-quo.”

More information about NestEgg Labs for investors can be found here.